Mount Pleasant Optimisation Project

Mount Pleasant Optimisation Project

The Optimisation Project was approved with conditions by the Independent Planning Commission on 6th September 2022. MACH Energy thanks all who made submissions. Further updates on development under SSD-10418 will be made in due course.

What does the Optimisation Project include?

The Optimisation Project would include:

- mining of additional coal reserves, including lower coal seams in North Pit;

- staged increase in extraction, handling and processing of run-of-mine (ROM) coal up to 21 million tonnes per annum as mining moves west, away from Muswellbrook;

- increase in average operational workforce to approximately 600 people, with a peak of approximately 830 people;

- giving up part of the approved disturbance area to compensate for new disturbance areas;

- rail transport of up to approximately 17 million tonnes per annum of product coal to domestic and export customers;

- use of innovative mine landform design to provide topographic relief and more natural exterior appearance of waste rock emplacement landforms;

- development of new water management and coal reject dewatering infrastructure;

- construction and operation of new ancillary infrastructure; and

- continuation of the Mount Pleasant Operation through to 22 December 2048.

The Project would provide community certainty for continuation of mining in the region and Mount Pleasant Operation’s continued support for local community groups and suppliers.

Mount Pleasant Optimisation Project Community Information Sessions

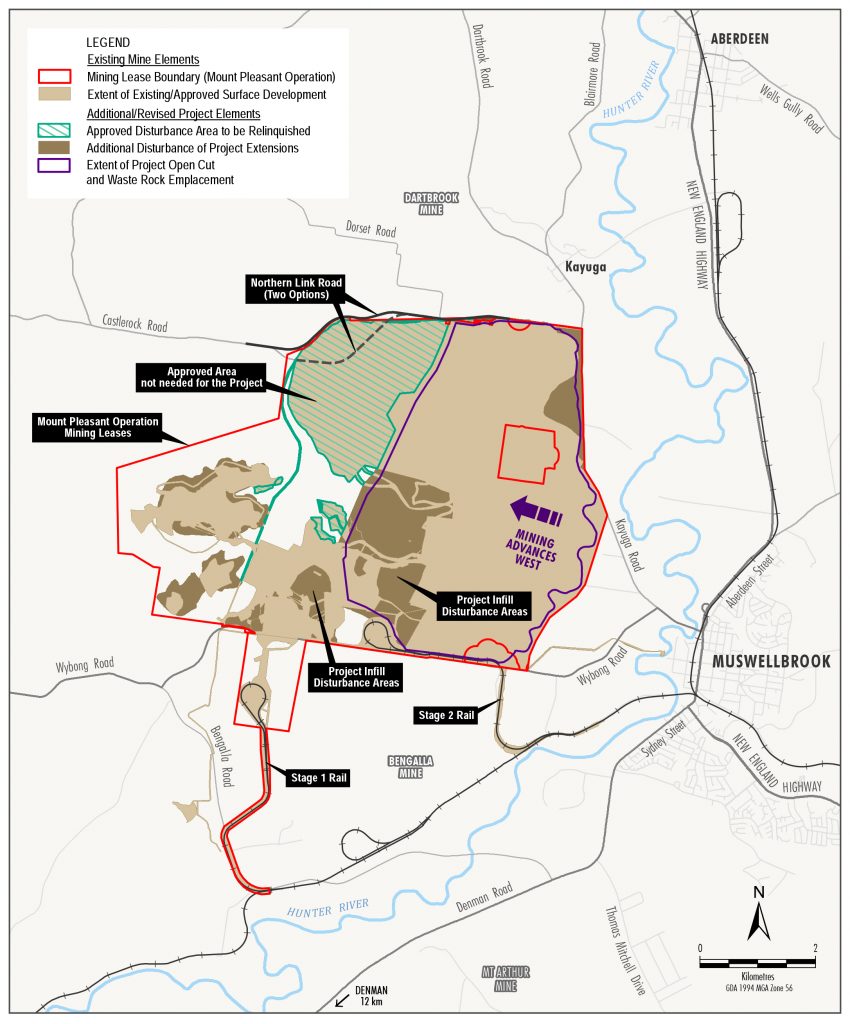

The following figure illustrates the approved area to be relinquished and Project extensions in the Mount Pleasant Operation Mining Leases. The Optimisation Project mining rate would be staged so it increases as mining moves further away from Muswellbrook.

State Significant Development Proposal – EIS

To enable the continuation of the Mount Pleasant Operation past 2026 we are required to submit a State Significant Development proposal.

As part of the proposal, we have prepared an Environmental Impact Statement (EIS) which includes assessments of the Optimisation Project’s potential social, economic and environmental impacts.

You can read more about the State Significant Development process on the NSW Government website.

Please visit the NSW Government Major Projects website to find information on the Optimisation Project, and associated NSW Government advice and requirements.

The Major Projects website Optimisation Project page includes the Optimisation Project EIS. The EIS exhibition period has now closed (17th March 2021). You can also download the EIS from our website using the link below.

Environmental Impact Statement (EIS)

5. Section 3 – Project Description

6. Section 4 – Strategic Context

7. Section 5 – Statutory Context

9. Section 7 – Environmental Assessment

10. Section 8 – Evaluation and Conclusion

12. Section 10 – Abb., Acronyms and Glossary

14. Att 2 – Assessment Requirements

15. Att 3 – Development Application Area and Real Property

16. Att 4 – Land Ownership and Landholder Key

17. Att 5 – Peer Review Letters

18. Att 6 – Strategic Planning Statements and Policies

19. Att 7 – Relevant Planning Instruments and Legislation

20. Att 8 – Rehabilitation and Mine Closure Addendum

21. Att 9 – Summary of Mitigation Measures

22. Att 10 – CIV Estimate Report

23. Att 11 – Consent under Section 380AA of Mining Act

24. Att 12 – JORC (2012) Summary

25. Att 13 – Geotechnical Considerations

26. Att 14 – Copy of Public Notice

27. Appendix A – Noise and Blasting Assessment

28. Appendix B – Air Quality Assessment

29. Appendix C – Groundwater Assessment

30. Appendix D – Surface Water Assessment

32. Appendix F – Aquatic Ecology Assessment

34. Appendix H – Historical Heritage Assessment

35. Appendix I – Agricultural and Land Resources Assessment

36. Appendix J – Road Transport Assessment

37. Appendix K – Geochemistry Assessment

38. Appendix L – Land Contamination Assessment

39. Appendix M – Visual and Landscape Assessment

40. Appendix N – Social Impact Assessment

41. Appendix O – Economic Assessment

42. Appendix P – Environmental Risk Assessment

43. Appendix Q – Preliminary Hazard Analysis

44. Appendix R – Human Health Assessment